Table Of Contents

Qualified Drain Layers

Qualified drain layers in Australia have a crucial role in ensuring efficient and effective pipe installation and repair. These professionals undergo rigorous training and certification to handle the complexities of drainage systems. With their expertise, they can accurately assess the requirements of a project and execute the installation or repair with precision.

The responsibilities of qualified drain layers are diverse and demanding. They not only install new pipes but also inspect and repair existing drainage systems. Their attention to detail and knowledge of best practices in pipe installation and repair guarantee the longevity and functionality of the infrastructure.

Installing and Repairing Drainage Systems

When it comes to the essential task of installing and repairing drainage systems, it requires a specific skill set and knowledge. Proper installation and maintenance of drainage systems play a critical role in ensuring the effective flow of water and preventing water damage in residential and commercial structures.

Pipe installation and repair is a job best left to qualified professionals who possess the expertise and experience to execute the task efficiently and safely. From determining the appropriate placement of the pipes to fixing any leakages or blockages, the process demands precision and attention to detail to guarantee a fully functional and long-lasting drainage system.

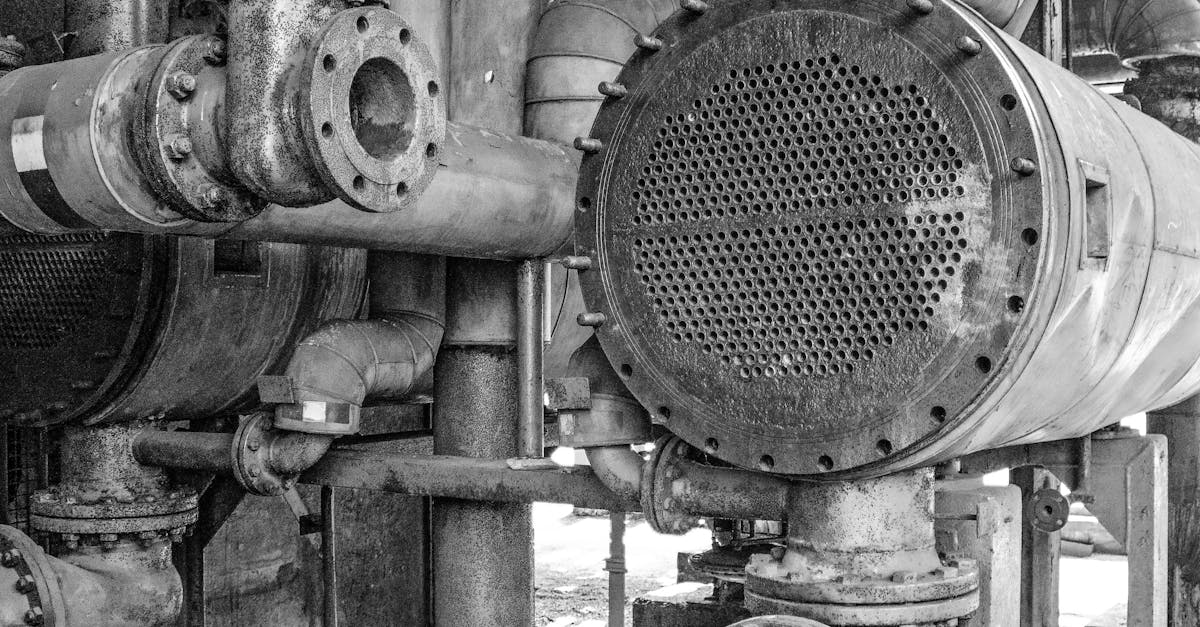

Pipe Welding Services

Professional pipe welding services play a crucial role in ensuring the efficiency and durability of pipe systems. Welding techniques are essential in connecting pipes securely and seamlessly to prevent leaks, damages, and potential hazards. With the expertise of skilled welders, pipe installation and repair can be carried out with precision and adherence to safety standards. Properly welded pipes are vital for various applications such as plumbing, industrial systems, and infrastructure projects.

Understanding different welding techniques is imperative for welders providing pipe welding services. Techniques such as arc welding, gas tungsten arc welding, and shielded metal arc welding are commonly used in joining pipes effectively. Welders need to possess a thorough knowledge of these techniques to ensure the strength and integrity of the welded joints. By mastering the intricacies of welding, professionals can contribute to the seamless functionality of pipe systems in diverse settings.

Understanding Welding Techniques

Understanding welding techniques is crucial for professionals involved in pipe installation and repair. Welding refers to the process of joining two pieces of metal together by applying heat and pressure to create a strong bond. In the context of pipe installation and repair, welding is commonly used to fuse pipes together to ensure seamless connections and prevent leaks.

Various welding techniques are employed in pipe installation and repair, with the choice of technique depending on factors such as the type of pipe material, the diameter of the pipes, and the specific requirements of the project. Common welding techniques used in pipe installation and repair include arc welding, TIG welding, MIG welding, and flux-cored arc welding. Each technique has its own set of advantages and limitations, and understanding the intricacies of each method is essential for achieving quality results in pipe installation and repair.

Specialised Pipe Materials

When considering pipe installation and repair, understanding the various specialized pipe materials available is crucial. Different projects require different materials to ensure durability and efficiency. One common type of specialised pipe material is PVC, which is known for its versatility and resistance to corrosion. PVC pipes are often used in household plumbing due to their lightweight nature and ease of installation.

Another important specialised pipe material is stainless steel, which offers superior strength and durability compared to other materials. Stainless steel pipes are commonly used in industrial settings and for underground water transportation due to their resistance to rust and corrosion. When selecting the right material for a project involving pipe installation and repair, it is essential to consider factors such as the environment, the purpose of the pipes, and the required longevity of the system.

Exploring Different Pipe Options

Exploring different pipe options is crucial when considering pipe installation and repair. In Australia, various materials are used for pipes depending on the intended use and environmental factors. One common option is PVC pipes, known for their durability and resistance to corrosion. PVC pipes are widely used in plumbing systems due to their affordability and ease of installation.

Another popular choice for pipe installations is copper pipes. Copper is valued for its longevity and ability to withstand high pressure and heat, making it suitable for both residential and commercial plumbing applications. Despite being relatively more expensive than other materials, the investment in copper pipes pays off in the long run due to their reliability and durability. Consideration of factors such as budget, location, and specific needs are important when weighing different pipe options for installation and repair projects.

FAQS

Who is qualified to fit and repair pipes?

Qualified drain layers are professionals who are trained and certified to install and repair drainage systems, ensuring the work is done correctly and meets industry standards.

What services do pipe welders offer?

Pipe welding services involve joining pipes together using various techniques to create a secure and durable connection. These services are essential for constructing or repairing pipelines.

How can I understand different welding techniques used for pipe fitting?

To understand welding techniques used for pipe fitting, it is advisable to consult with experienced professionals who can explain the processes involved, such as TIG welding, MIG welding, and stick welding.

What are specialised pipe materials used in pipe fitting and repair?

Specialised pipe materials, such as PVC, copper, and stainless steel, are commonly used in pipe fitting and repair to ensure longevity, durability, and efficiency of the drainage system.

How do I explore different pipe options for fitting and repair?

To explore different pipe options for fitting and repair, you can consult with experts in the field who can provide information on the pros and cons of various materials and help you select the best option for your specific needs.